products / paper, tectum

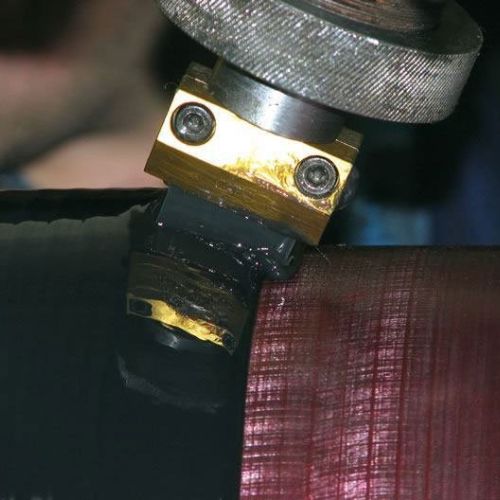

Polyurethane rollers' covers — regeneration

As a result of many years of experience with polyurethane systems and thanks to the constant expansion of our machinery stock, we offer you regeneration of the rollers’ cover.

Regeneration includes:

- removal of old and damaged coating,

- replacement of rollers’ cover bearings,

- axle recovery,

- repair of rollers’ cover surfaces,

- implementation of new polyurethane coating,

- grinding of new coating,

- dynamic balancing.

Our L-PUR coatings are characterised by:

- hardness in the range of 35 ShA – 65 ShD,

- very good dynamic properties,

- very high resistance to abrasion,

- capacity to work under a wide pH range,

- good anti-static properties on the coating (NO overlying microbial cellulose).

Coatings of this type significantly extend the maintenance-free period for all sections of the paper machine.

Thanks to our well-developed CNC machining centre, we are able to perform any type of coating treatment andtype of cut (cylindrical, bombarded, banana, cut, with a snake, etc.)