Using innovative solutions to unlock the potential of the company

The main aim of the project, that was carried out since October last year, was implementing innovative solutions in designing molds by stimulating the imagination and the creativity of our designer engineers. The project, carried out individually by each of our designer engineers, consisted in conducting a thorough analysis of a problem, choosing the solutions, designing a new mold model in the SolidWorks software and then making it. The idea was to modify the mold in such a way that the finishing processes and the time of die exchange would be minimized, the work of people would be made more effective, and a higher quality of the product would be ensured.

After the stage of design the mold underwent tests in the foundry during which its compliance with project objectives and guidelines was evaluated.

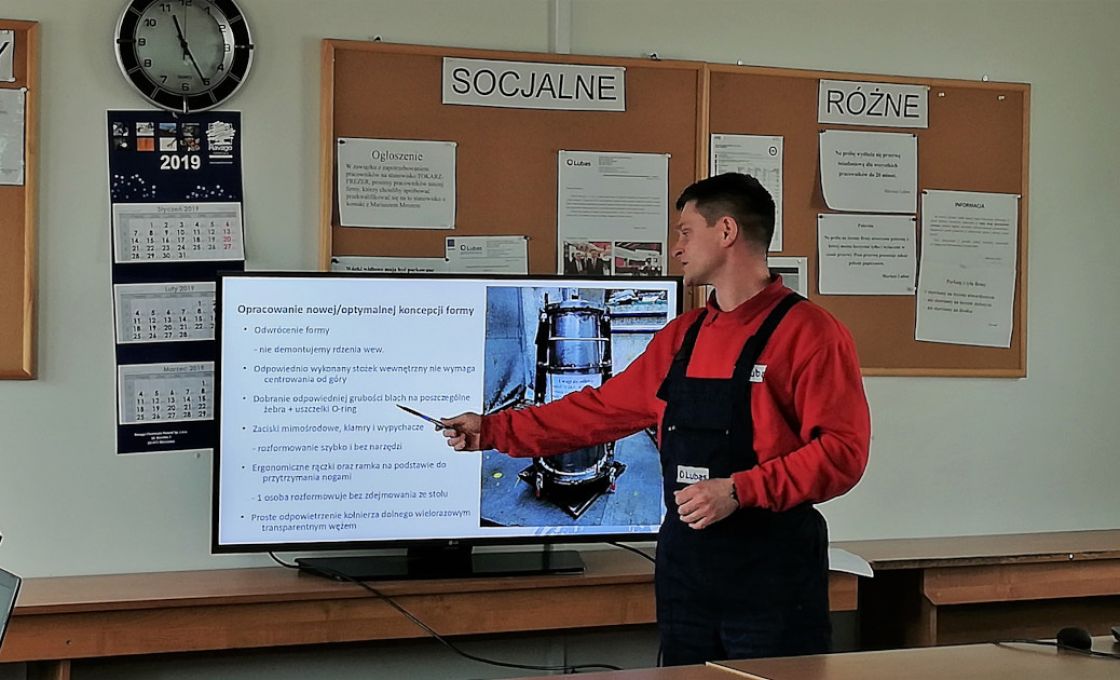

Each engineer gave a presentation, and their work was assessed by Mariusz Lubas, the CEO, and the Development Department consisting of the management staff.

The project was a part of a strategy that is pursued by the company, according to the objectives of Lean Management and the Kaizen philosophy, as continuous improvement.

Photograph shows the prize winner, Mariusz Królicki, a design engineer whose modernisation of the hydrocyclone lower cone lining mold proved to be the best.