products / stone industry

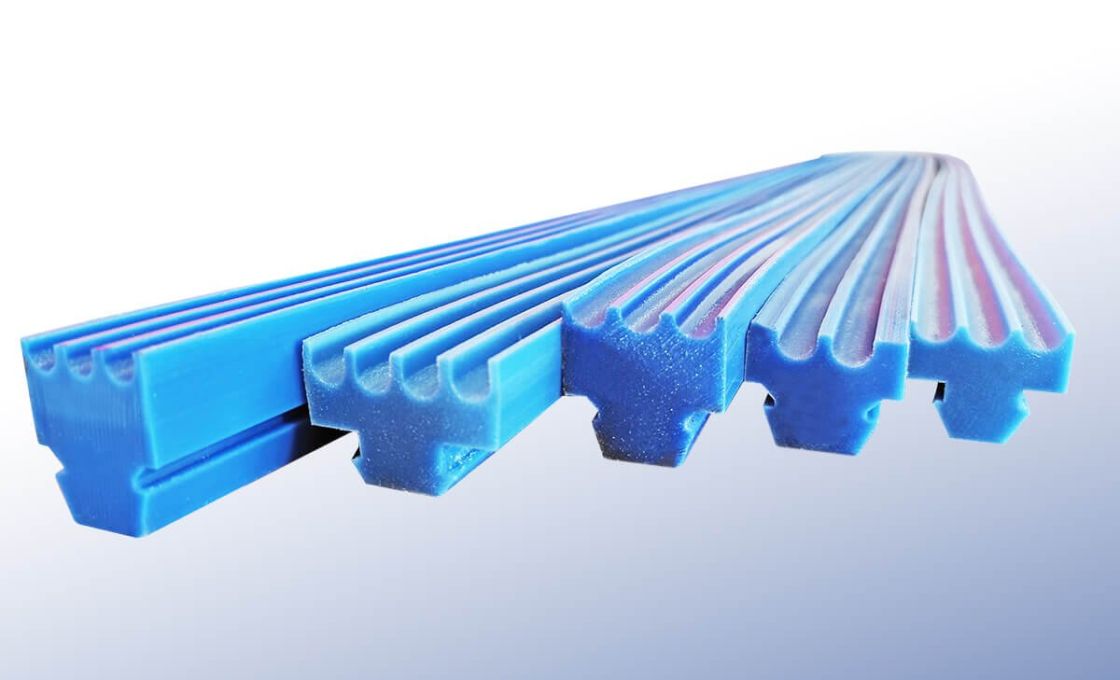

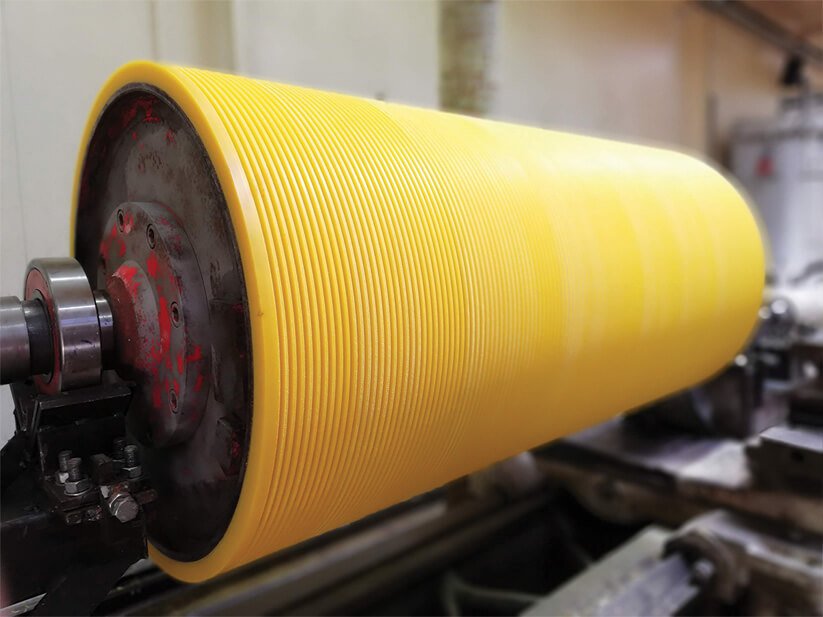

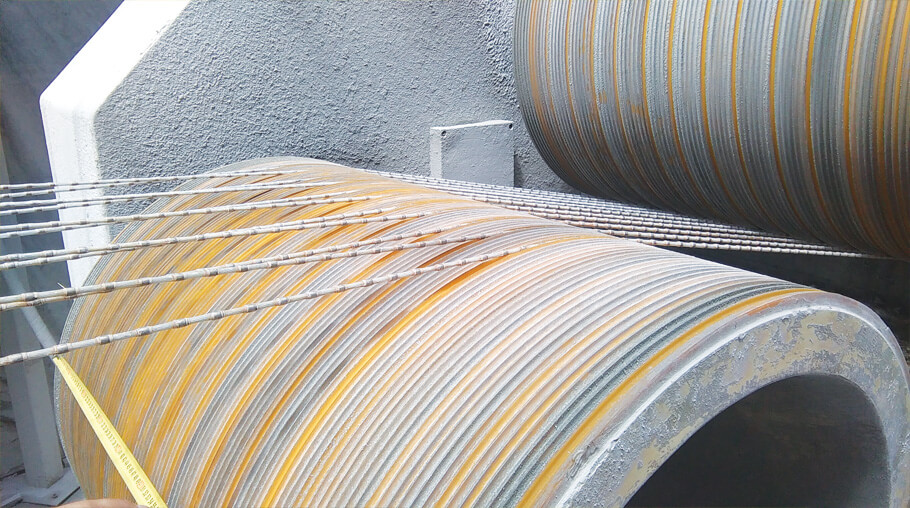

Production of profiles for

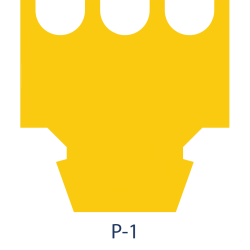

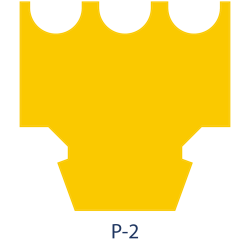

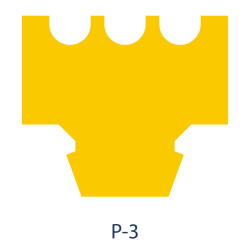

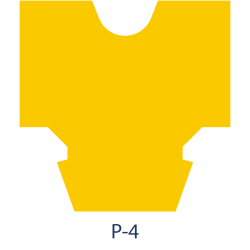

single- and multi-wire saw wheels

Profile production

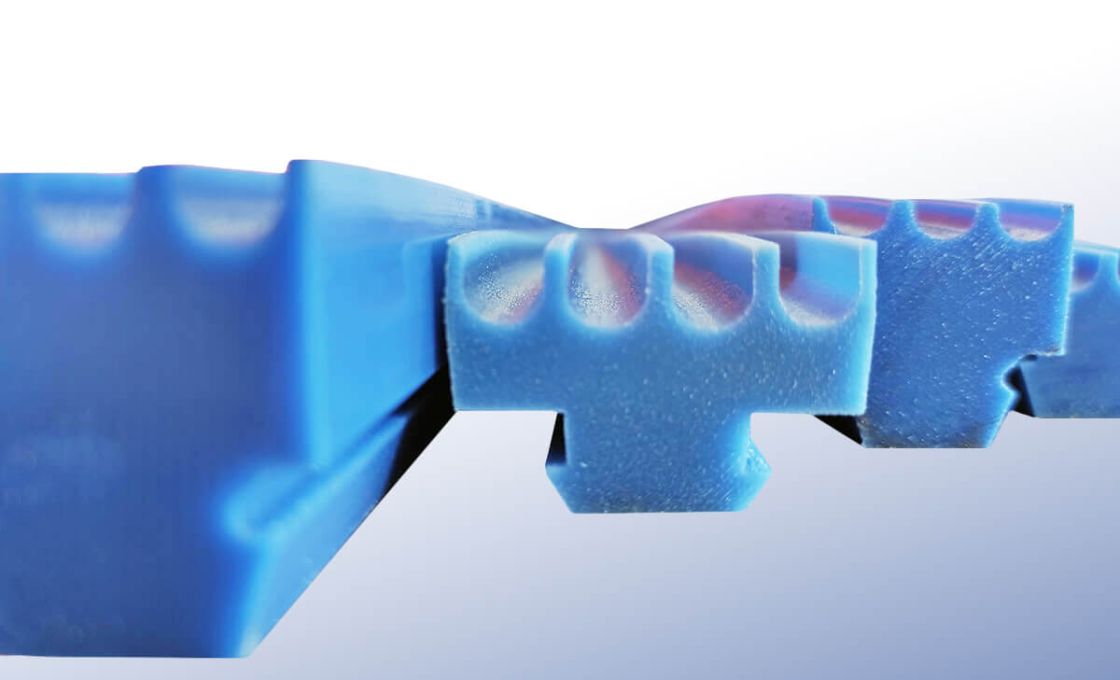

As the leading company in Europe, Lubas manufactures profiles for wire saw wheels using an innovative continuous casting process. This type of casting ensures process stability and product uniformity to guarantee quality repeatability.

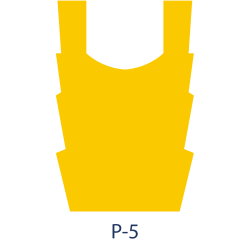

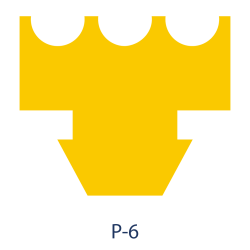

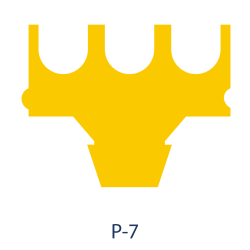

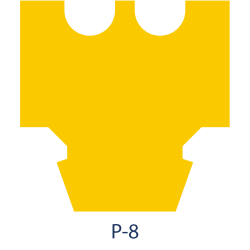

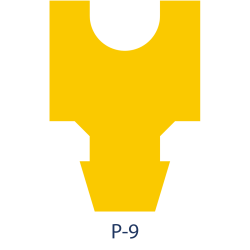

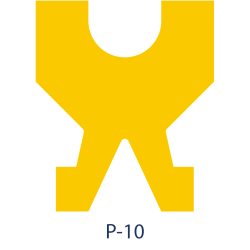

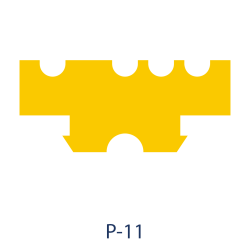

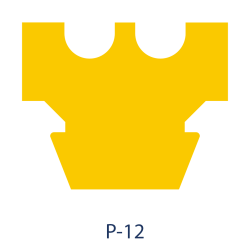

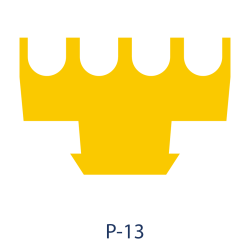

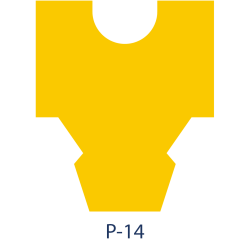

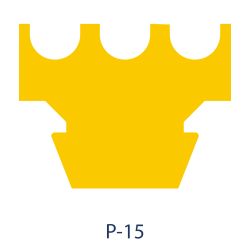

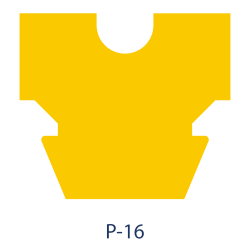

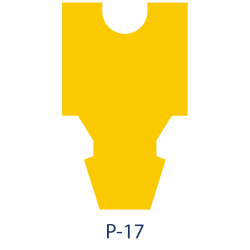

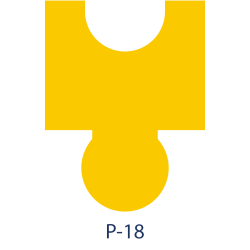

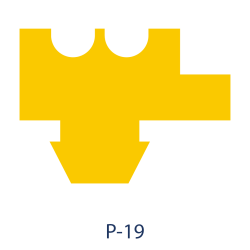

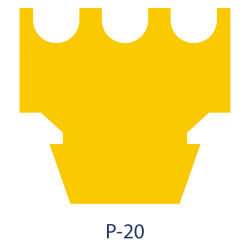

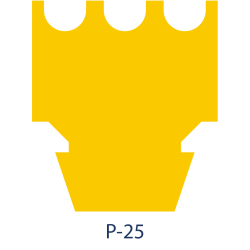

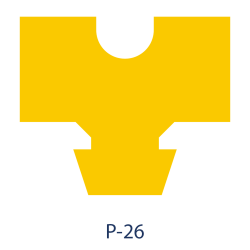

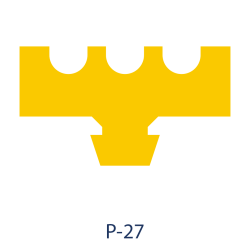

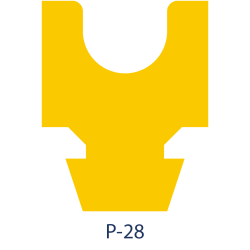

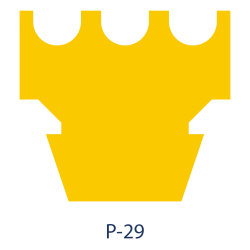

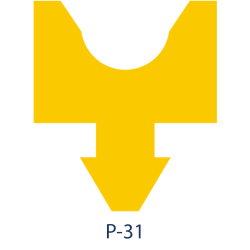

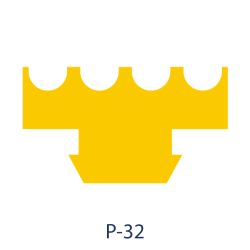

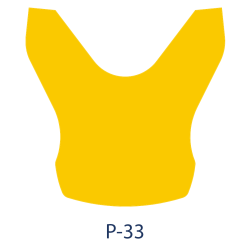

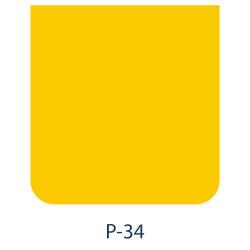

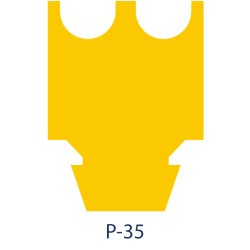

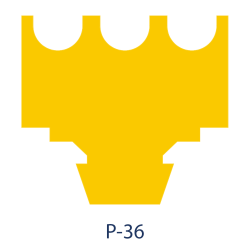

The wide Lubas offer currently includes over 30 various types of profiles compatible with the machines of all European stone cutting machine manufacturers.

With the extensive R&D department, any shape can be manufactured.

As part of our comprehensive service of manufacturing profiles for wire saw wheels, we perform the following activities:

- mould design (for a new profile),

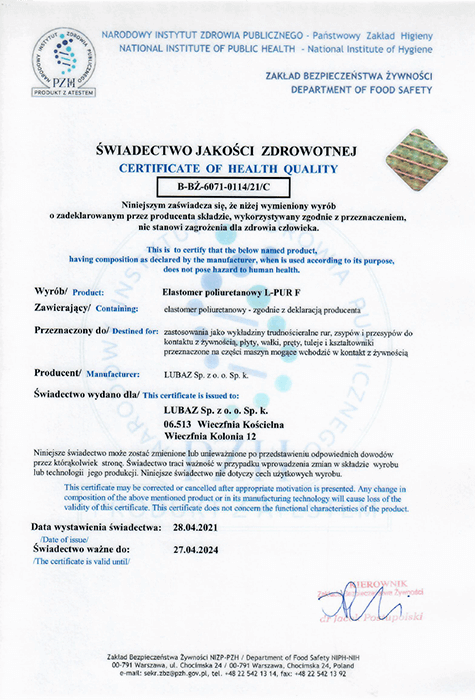

- casting using the L-PUR polyurethane elastomer,

- verification of dimensions by the Engineering Department.

The Lubas offer for the stone industry ensures:

- easy assembly,

- high abrasion resistance,

- bracket production precision,

- precise slab cutting,

- operation continuity.

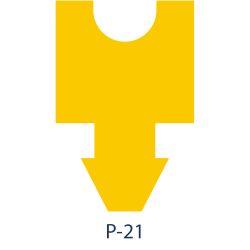

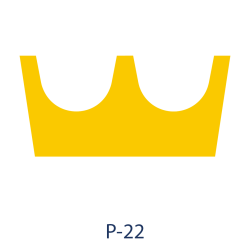

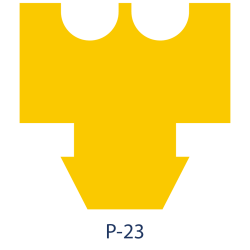

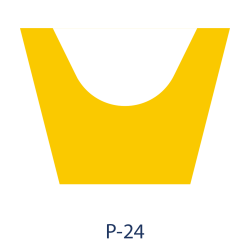

Profiles for single- and multi-wire saw wheels

The Lubas offer includes over 30 standard profiles for single- and multi-wire saw wheels.

Purpose of profiles

Our own spare parts compatible with the products of the following brands:

- Pellegrini,

- Bidese,

- Breton,

- Pedrini,

- BM,

- Socomac,

- Simec.

L-PUR polyurethane

With the L-PUR polyurethane by Lubas for stone industry industry, you will receive:

- extended product life guarantee,

- production precision,

- surface durability.

Features of the L-PUR polyurethane:

- high abrasion resistance,

- elasticity,

- corrosion protection,

- quiet operation.

Accessories

Our offer also includes accessories such as:

- linings (e.g. 8×40, 8×46),

- bearings,

- sleeves,

- wheels.

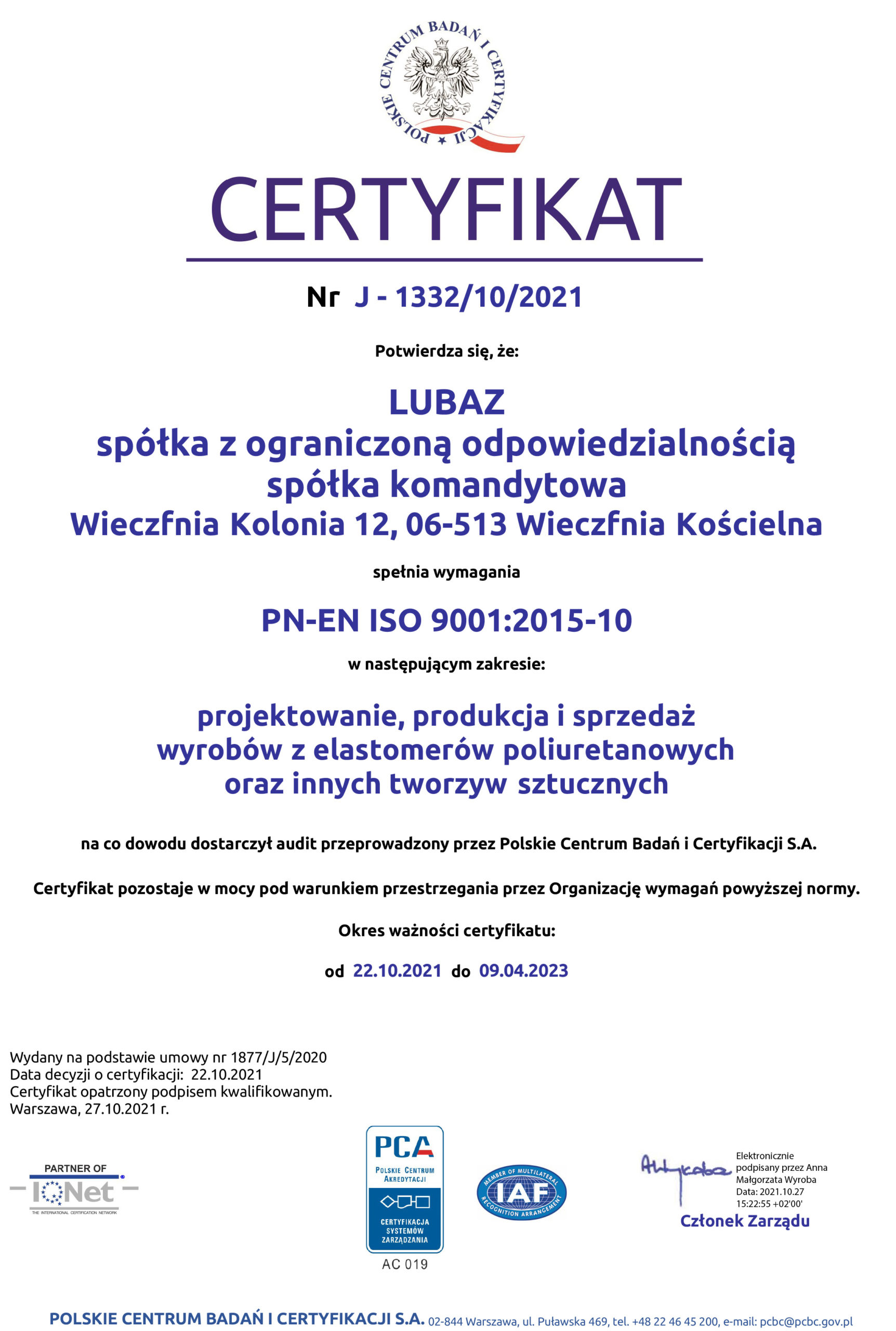

About us:

Lubas is a family business, which for 30 years has been manufacturing products made of L-PUR polyurethane elastomers. These materials have a wide range of applications and are perfect for many industry branches – from the mining industry to the furniture industry.

Currently, LUBAS is a modern plant with multiple departments that perform a dozen or so technological processes, all of which operate simultaneously.

The heart of the company is a polyurethane elastomer casting house and an autonomous engineering/construction department with advanced 3D technologies and a mechanical department with CNC machines.

Sales are made to 42 countries across 6 continents, with the manufacturing plant being located in the Mazowieckie Voivodeship, Poland.