products / loose treatment abrasive

Vibratory bowls – vibrating equipment

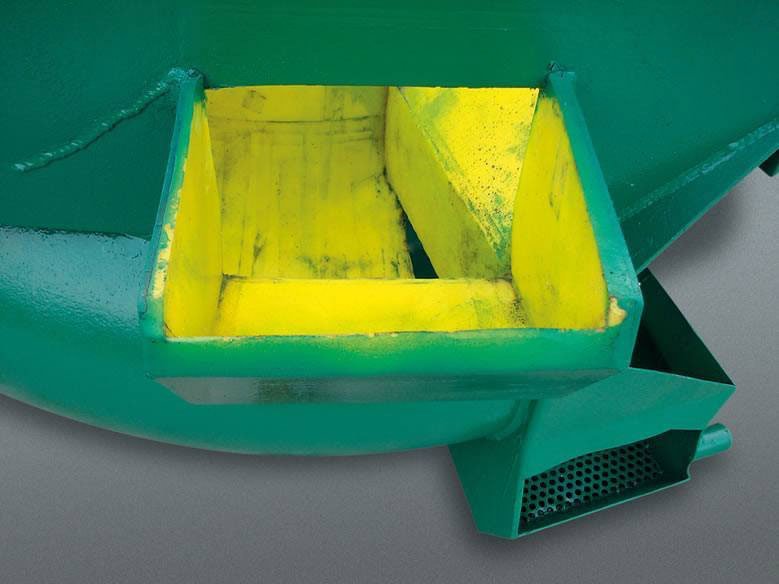

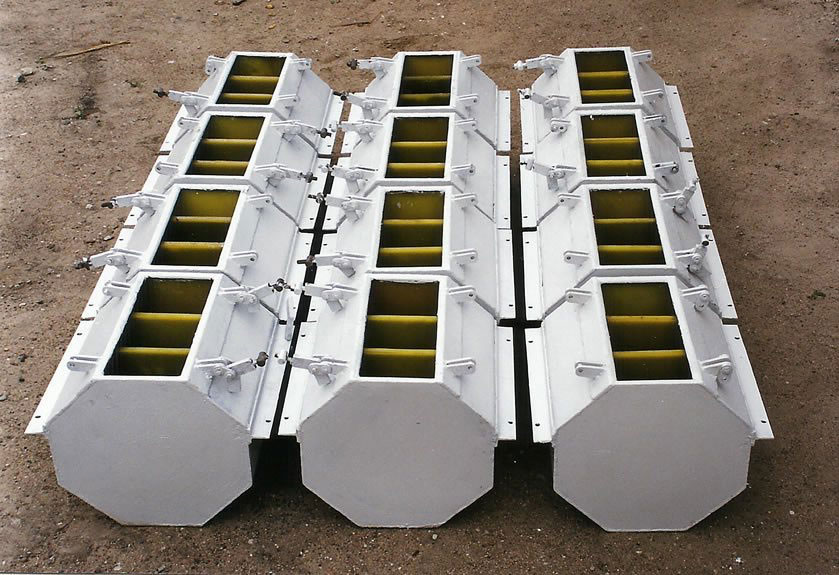

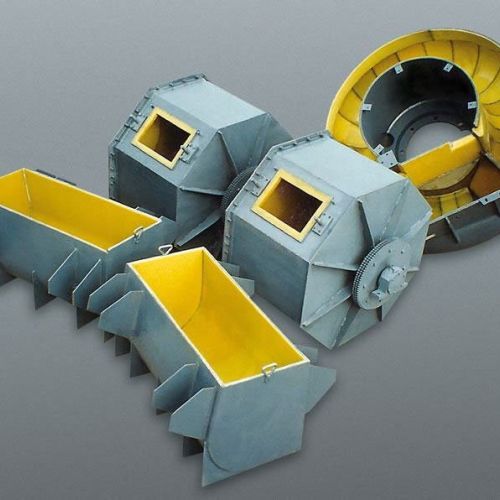

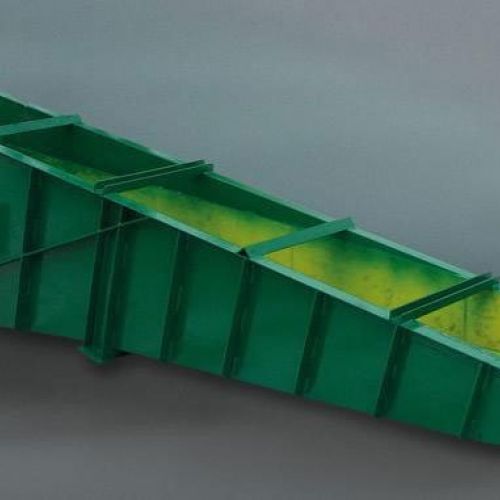

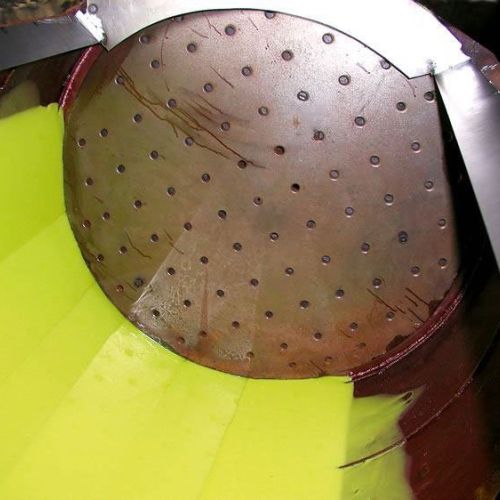

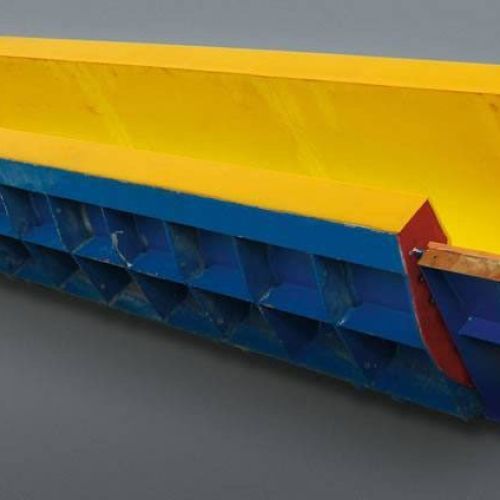

Regeneration of working part consists of covering the metal structure of the device with specially selected L-PUR elastomer. Experience in the field of equipment regeneration allows us to be a market leader.

Our service guarantees:

- A long working life even in the most overloaded machines.

- Co-operation both with small workpieces such as cutlery and large massive and sharp castings.

- The warranty on the adhesion between the L-PUR elastomer and the steel structure.

- Work in heavy and chemical environments with liquids supporting processing.

- Resistance many times larger than that of rubber.

- Does not get workpieces dirty.

- Lining does not flake.

We regenerate all the devices present on the market including from most popular manufacturers such as:

- Walter Trowal,

- Rösler,

- Erba,

- Avalon,

- Vibromak,

- Kromas.

Due to the wealth of experience collected over the years, we are able to choose the most appropriate technology for the regeneration of the machine and the nature of its operation.

Thanks to our expanded regeneration department for vibration abrasive machining machines, we can offer the regeneration using the following methods:

- Monoblocks cast as a single unit. One cast without joints.

- Lining with plates.

- Spraying.

- Combined method – division of the unit due to work zone loads.

List of operations:

- Inspection, examination of the machinery.

- Removal of old lining (if polyurethane, included the price), removal of rubber lining is treated as an additional service that needs to be arranged.

- Bench work on the housing.

- Preparation of equipment surface for pouring L-PUR polyurethane elastomer.

- Pouring of L-PUR polyurethane elastomer.

- Machining of L-PUR polyurethane elastomer.

- Regeneration of the machine elements such as plugs, fillers, sieves.

- Painting, maintenance of metal outer surfaces of the device.

We regenerate and repair all types of vibration abrasive machines including:

- Rotor-cascade vibratory bowls

- Gutter vibratory bowls

- Classic vibration vibratory bowls

- Spiratron vibratory bowls.

Our service guarantees:

- Long-term operation of lining in the busiest machines.

- Strength many times greater than rubber lining.

- Does not get workpieces dirty.

- Lining resistant to enhancers.

- Machining accuracy of rotor-cascading vibratory bowls and moving parts of vibration vibratory bowls.

- Ability to regenerate both jewelery vibratory bowls and long drums and gutters.